Studio Carminati - Competenze nel Project Management specifiche per la Gestione ed Esecuzione di Contratti-Progetti Service per l'Industria 4.0

Studio Carminati - Competenze nel Project Management specifiche nella gestione ed esecuzione di contratti-progetti service (field/post-vendita) per il comparto nazionale ed estero dei beni strumentali industriali "software-intensive", applicazioni (greenfield/brownfield) d'automazione industriale (discreta-meccatronica-elettronica di potenza) basate sull'uso di azionamenti-motori elettrici ed emergenti tecnologie Industria 4.0

Grazie al consolidamento della recente business partnership con un interim manager esterno, Studio Carminati (già da anni esperto nella gestione economica di progetti e servizi su commessa per la sola micro-piccola impresa) è in grado di operare in base a processi "project-based" in contesti molto più estesi e complessi come quelli appunto dei contratti e progetti service nazionali-esteri (field/post-vendita) per il comparto dei beni strumentali industriali "software-intensive", applicazioni (greenfield/brownfield) d'automazione industriale (discreta-meccatronica-elettronica di potenza) basate (principalmente) sull'uso di azionamenti-motori elettrici ed emergenti tecnologie Industria 4.0.

Il tutto secondo le metriche, modalità e limitazioni descritte in questo mansionario interno in lingua inglese realizzato in base alle competenze ed esperienze (dirette, documentate) più autorevoli e recenti del nostro business partner che ha precedentemente ricoperto (in multinazionali italiane) ruoli tecnici da trasfertista (commissioning engineer, site-commissioning manager lato discipline elettriche, elettromeccaniche, elettrostrumentali, automazione di fabbrica-processo) e gestionali (PMO, project-service manager con responsabilità lato commerciale, contrattuale, tecnico-economica, esecutivo-operativa, logistica, viaggi-missioni di lavoro, HSE, dispute-contenziosi) specializzandosi dal 2011 al 2018 (presso una storico OEM italiano oggi parte di una multinazionale americana-giapponese) nei processi di fornitura, gestione, esecuzione progetti, servizi tecnici “avanzati” in appalto-subappalto di field service, service post-vendita per le complesse applicazioni (MV Large Drives & Power Conversions-Electronics) d’automazione industriale e azionamento-propulsione elettrica all’interno del comparto EPC (large capital projects) oltre che in fabbriche-stabilimenti manifatturieri, industrie pesanti, impianti oil&gas, petrolchimici, centrali elettriche, infrastrutture critiche, piattaforme offshore, navi (porta container, posatubi, posacavi, esplorazione petrolifera, costruzione offshore, rompighiaccio, difesa).

Addestrato nelle procedure HSE per le trasferte, cantieri esteri con focus extra-professionale su nuova ISO 31030 (travel risk management) oltre che della più generale ISO 31000 (in combinazione con la OSHAS 18001-ISO 45001) per i lavoratori trasfertisti in solitario.

Conduzione di trasferte e cantieri esteri (anche in heavily regulated countries, marine, off-shore, hazardous areas, harsh/hostile environments) in Italia, Francia, Regno Unito, Germania, Danimarca, Spagna, Cecoslovacchia, Romania, Austria, Olanda, Suriname, Brasile, Messico, Panama, Argentina, Stati Uniti, Giappone, Cina, Malesia, Vietnam, India, Pakistan, Bangladesh, Canada, Federazione Russa, Congo, Angola, Sudafrica, Israele, Kuwait, Qatar, UAE, Algeria, Giordania, Oman, Arabia Saudita, Egitto, Libia, Tunisia, Iraq.

Per più di 8 anni ha lavorato all'estero per l'industria ceramica, vetro cavo e global service impianti tecnologici in: Taiwan, Cina, Hong Kong, India, Giappone, Filippine, Vietnam, Egitto, Turchia, Olanda, Stati Uniti, Argentina, Panama, Brasile, Egitto, Spagna, Germania, Francia, Iran, Zimbabwe, Turkmenistan, Haiti (e più recentemente per l'impiantistica industriale EPC e navale con brevi missioni anche in Algeria, nuovamente India, Olanda, Francia, Giappone, Germania).

In più di 25 anni di lavoro continuativo nel comparto industriale ha inoltre maturato una forte esperienza (supportando anche i legali interni/esterni ed assicuratori del credito-sinistri delle aziende per le quali ha lavorato) nella negoziazione, risoluzione, mitigazione di dispute “high-stakes situations” commerciali nazionali-internazionali (escalations, rivendicazioni-inadempimenti contrattuali “claims”, riaddebiti “back-charges”, risarcimenti “liquidated damages”, penali, varianti, insoluti) nei progetti (greenfield/brownfield) e relativi servizi tecnici su commessa operati in campo-cantiere (appalti/subappalti field service all’interno di EPC megaproject TIC > 0,5 billion US$) specificamente su:

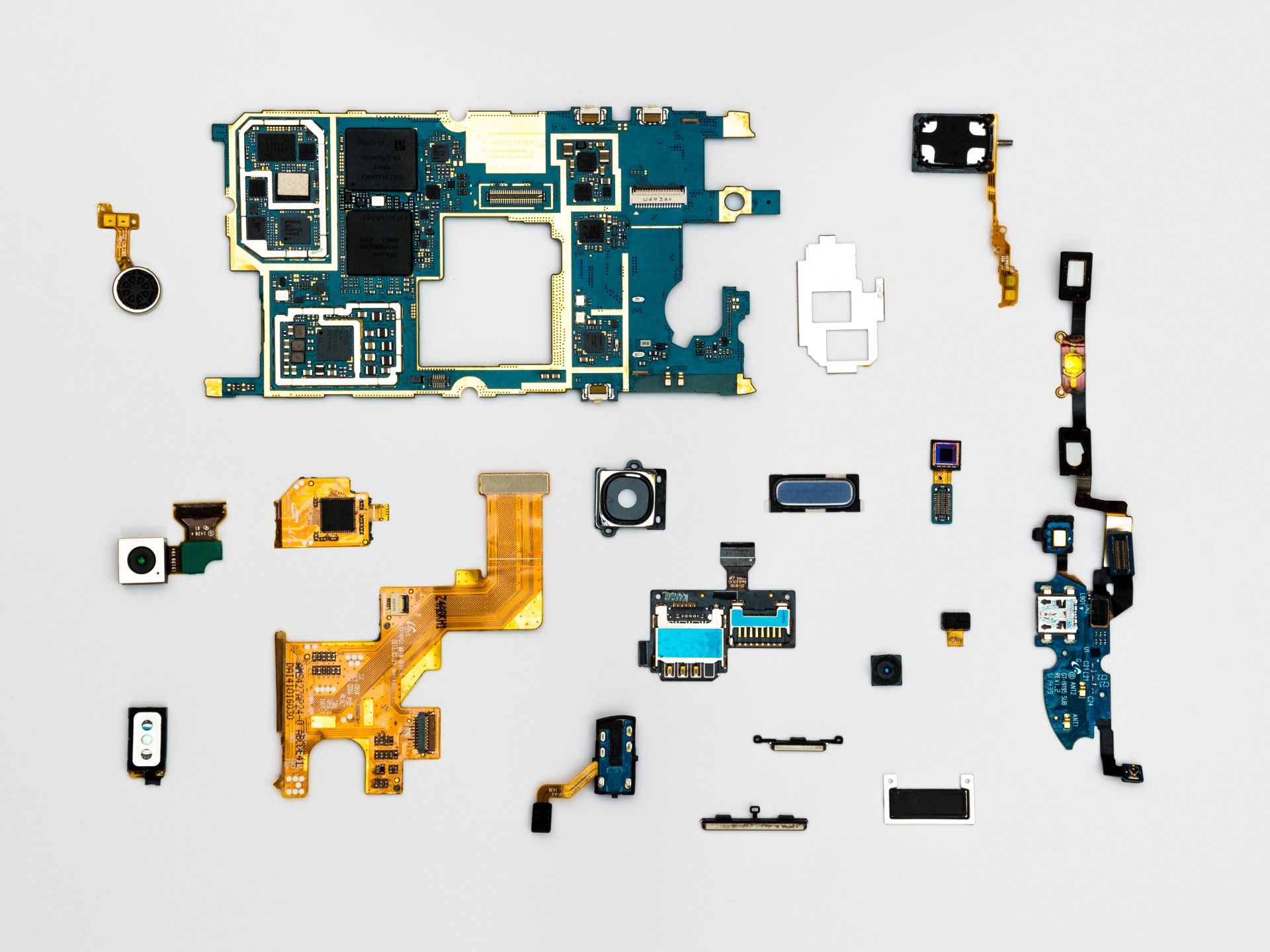

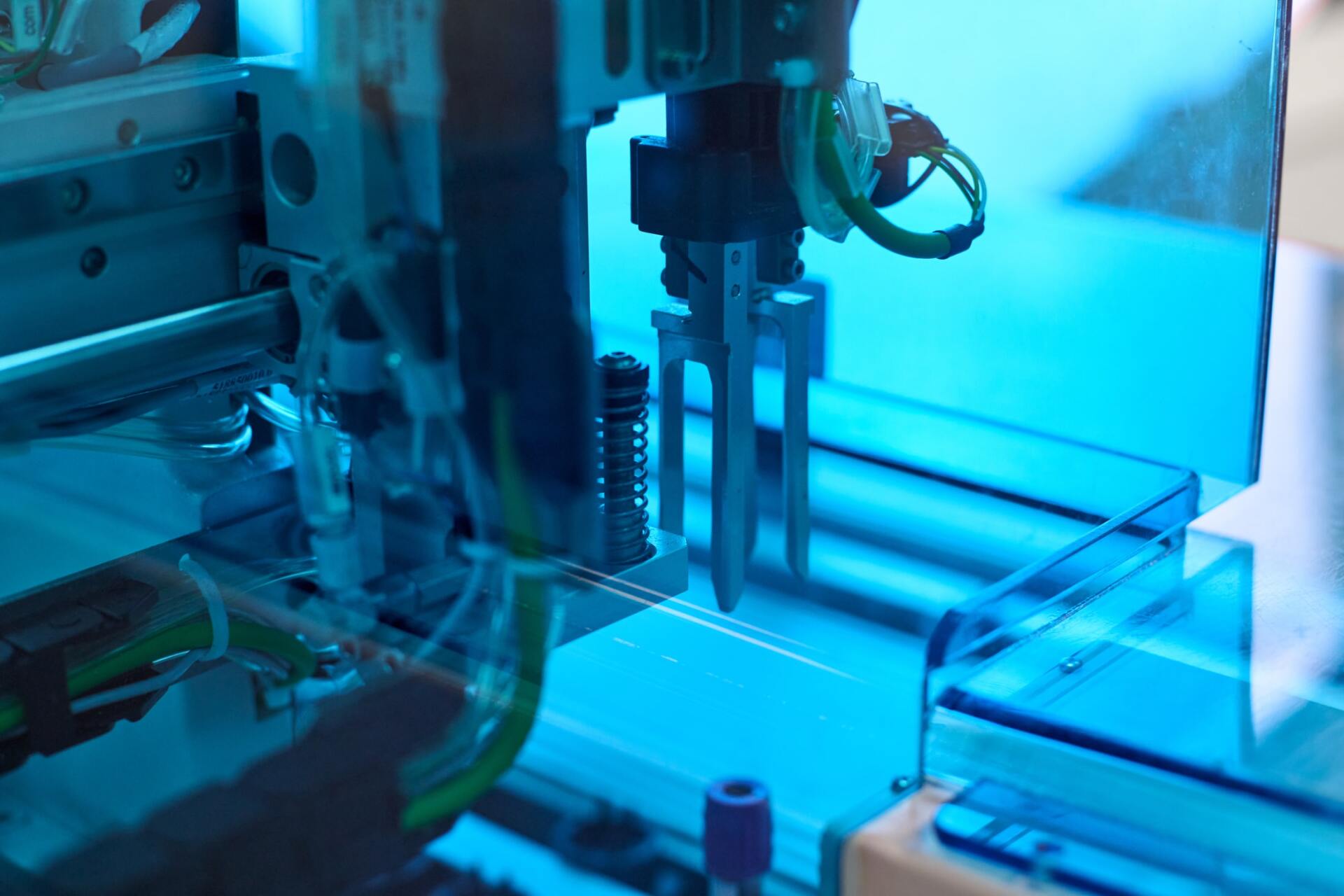

- architetture informatiche industriali (OT & Embedded) dei sistemi “software-intensive” SCADA/ICS/IACS di supervisione, automazione, controllo (e relativa quadristica elettrica di comando, bordo macchina, elettronica di potenza) per applicazioni principalmente basate sull’utilizzo di azionamenti, motori elettrici

- emergenti tecnologie digitali “Industria 4.0” in particolare lato adozione dei dispositivi di telemetria, monitoraggio, diagnostica, manutenzione predittiva, assistenza remota nelle applicazioni di automazione discreta-meccatronica-elettronica di potenza

Comprovata competenza lato “execution/operations” oltre che contrattuale, organizzativa e negoziale, volta alla prevenzione e/o successiva mitigazione/risoluzione delle problematiche del comparto service post-vendita industriale & field service in campo, cantiere, offshore. Skills economico-finanziari supportati dall’aiuto di proposals, controllers di B.U./commessa e strumenti ERP evoluti (NO fogli Excel da aggiornare manualmente & tools macchinosi-complicati-manuali come Microsoft Project desktop) in grado di generare in automatico la necessaria reportistica di avanzamento commesse.

- gestione multi-commessa (a matrice/cross-functional con punte massime di 50 persone coordinate “in contemporanea” su più progetti concomitanti) basata su metodologie waterfall/PMBOK/V-Model e l’uso di gestionali ERP dedicati (SAP R/3 PMIS) al project management & cost/project control

- direzione esecutiva operazioni in campo e ammodernamenti in subappalto per progetti EPC o impianti, fabbriche esistenti

- responsabilità dello scopo di fornitura e conto economico per un backlog ordini service medio di 8 M€/anno per interventi (prestazioni tecniche in campo, forniture ricambi, progetti d’ammodernamento, consulenze per l’ingegneria di manutenzione-asset management) su una base d’installato “capital-equipment” media di 50 M€/anno, 12.000 giorni-uomo/anno, mediante meccanismi di attivazione/gestione risorse di commessa basate su flussi interplant, intercompany, subappalto

- Interface management (comunicazione per l’esecuzione di progetto) con un carico massimo di 150 interlocutori/mese (tra personale interno, interplant-intercompany, in subappalto, del cliente e stakeholders)

- report diretto anche nei confronti della C-suite (VP, CFO, CTO, COO) interna, revisori esterni (personale di multinazionali statunitensi comparto financial audit (SOX/compliance) & assurance consultancy/management) e project director EPC (EPC megaproject TIC > 0,5 billion US$) cliente

[ENGLISH]

All project management assignments (mainly waterfall/PMBOK-based since Lean/Agile methods are not always suitable in the yard/site/field/plant-floor operations or EPC subcontracts executed with active/passive contractual claims clauses, bank guarantees, performance/warranties bonds) will be delivered according to the below list of metrics, processes, skills, and capabilities:

Domestic and international contract and project management metrics

– EPC project management domains, based on waterfall/PMBOK/V-Model methodologies and the use of Office 365 jointly with SAP PMIS ERP

– financials progress (in multi projects) managed jointly with the cost controllers, the use of dedicated costs & projects control ERP modules to collect and measure in automatic projects KPIs (costs, markups, profits, reserves, variances)

– subcontracted field service operations in new industrial EPC projects or existing-modernized end-users industrial plants, heavy industries, manufacturing factories, critical infrastructures, and marine vessels – offshore platforms

– scope and P&L accountability for an average backlog of field interventions of 8 M€/year, 12.000 man-day/year deployed on concurrent projects/contracts including interplant, intercompany, subcontracted activities

– interface management with a peak load of around 150 different internal/customer project teams/stakeholders

– reporting capabilities with C-suites, external financial auditors, and client’s senior executives, megaproject directors (TIC > 0,5 Billion US$)

– prompt interventions for escalations, international commercial dispute mitigation/resolution strategies, and operations on after-sales service agreements

Planning & Controlling (only on SAP R/3 PMIS ERP. The project management, project control, costs control skills are not deployable with unsuitable tools like basic-simple ERPs without project-based cost management modules, or project & service management financial processes based only on the use of Office 365 tools)

- manages the project (contract/agreement) within the contractually defined quality framework (time, budget, functionality) from kick-off to final acceptance.

- chair the kick-off and define with the support of the lead project engineer, production manager, and buyers the project schedules, milestones, WBS, CBS, technical staff, and the sub-project handover to main contract partners, subsidiaries, and interplant units

- handles the forecast costs allocations, all relevant planning elements (materials, equipment, services, resources), and milestone work results, according to the defined programs/projects portfolio

- sets up and maintains the internal project management plan

- defines procedures and requirements concerning quality management (audits, system tests, acceptance checks) according to internal/customer quality management standards

- monitors continuously the project status (taking into account financial target), early identification of discrepancies, and initiates targeted correction actions

- holds regular project status meetings, prepares progress reports, and organizes acceptance of milestone work results

- manages the acceptance of delivery units and services, performing quality controls and internal/external expediting/correction actions

Engineering Management

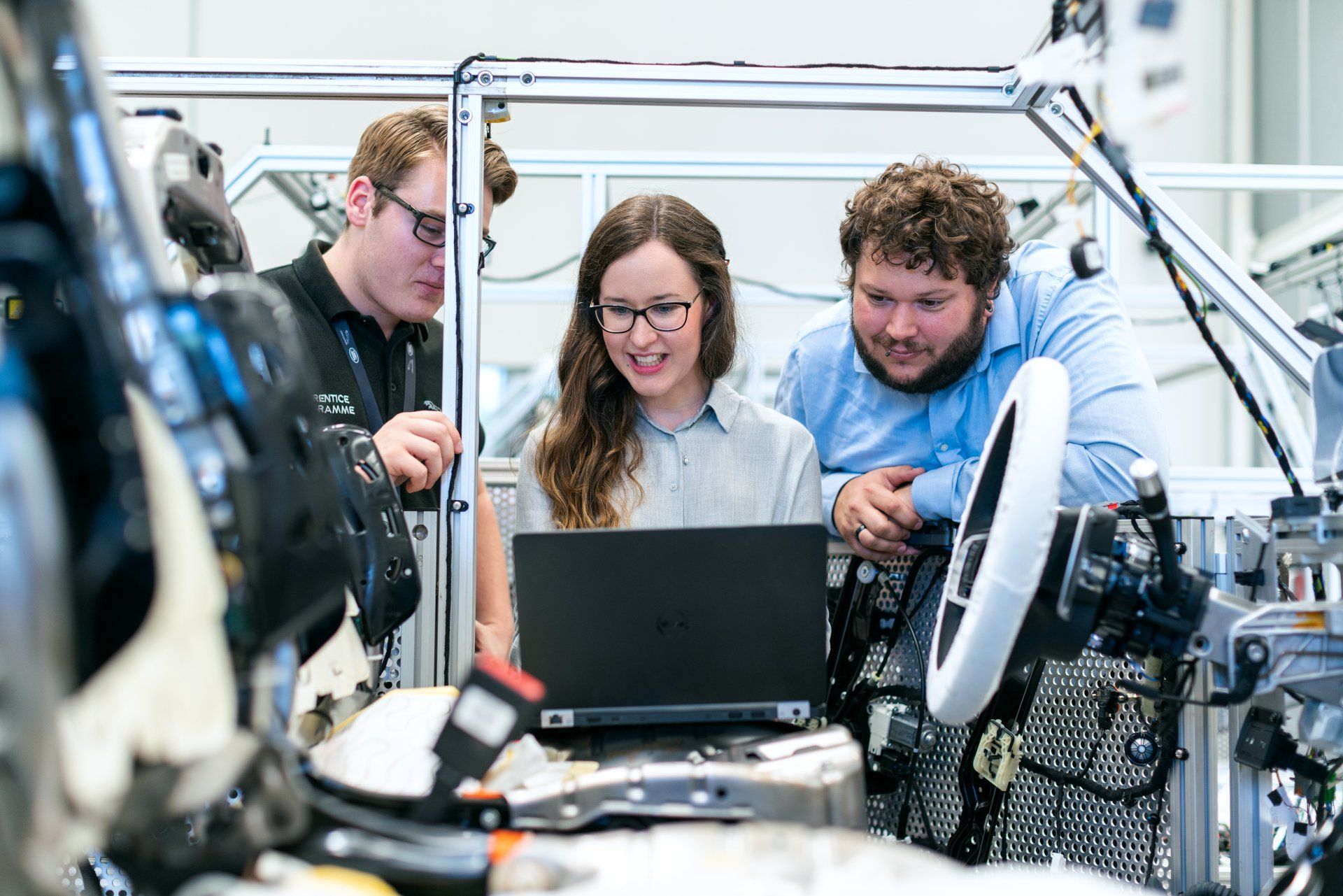

- collaborate (integrating project and system engineering domains) with the lead project engineer on the management of the engineering team (control engineers, automation engineers, mechanical engineers, electrical engineers, systems engineers, systems integrators, developers, networking engineers, and cybersecurity professionals) ensuring that staff has an appropriate project understanding

- takes leadership of and provides directions and communications to the engineering team, internal/external suppliers/developers partners, subsidiaries, and interplant units

- participates together with the lead project engineer in meetings and surveys with internal suppliers/developers partners, customers, consultant engineers, third-party agencies, quality assurers, IP specialists, and subcontractors regarding project activities

- reviews engineering and technical drawings, documentation, procedures, and studies in compliance with stipulated, requirements, guidelines, and technical standards

- reviews all required engineering standards and regulations

- monitor systems engineering procedures, engineering deliverables progress, software release schedules, and expedite design/workflow

- during field service operations, support the field service coordinators to promptly involves the relevant engineering specialists to guide the field engineers team and participate in the conference call or customers meeting

Customers Management

- operates as the main project interface actively gathers information on the customer and the customer’s requirements/targets

- involves the customer in decision-making, provides regular information and feedback

- manages customer expectations and concludes the project to the satisfaction of the customer

- identifies cross-division business opportunities

- creates additional business opportunities out of the ongoing project

- devises and implements strategies for strengthening market and customer commitment

- negotiates and mitigates with the customers all the critical project issues

Proposal/Contract Management

- participate in the bid preparation for projects and spare parts (SPIR FORM) offers

- analyzes customer requirements, clarify and examines their technical feasibility and transferability into a bid

- ensures that the technical and commercial approval process with all risk assessments (including compliance) is followed

- examines the bid costing in terms of financial efficiency

- ensures that incoming order specifications (scope, requirements) and costing are done and documented

- involves the relevant partners in the bid phase.

- ensures that all planning elements (e.g. system structure, work breakdown structure) are included in the bid phase

- influences formulation of the constraints of contracts

- ensures that the results of risk assessments and compliance risk assessments are appropriately addressed in contracts and in costing

Site Management and HSE

- promoting QHSE compliance at every opportunity, escalating any integrity issues

- collaborate with the field service coordinators on the management of the field service team ensuring that staff has an appropriate project understanding and all the required tools/instrumentations are available to perform the planned activities

- collaborate with the HSE and field service coordinators for all HSE processes, documentation, training, and equipment.

- collaborate with field service coordinators for all VISA, travel, personnel Oil&Gas certifications, BOSIET, gate pass, and logistics issues of the sites/yards/vessels.

Risk & Opportunity, Issue Management

- throughout the project life cycle, identifies and assess all risk factors utilizing available information and risk measurement tools

- devises suitable strategies for risk mitigation (elimination, reduction)

- implement the procedure for solving issues and problems (identification, analysis, actions, and controlling) with all necessary internal and external partners/stakeholders

- identify and minimizes non-conformance costs

- manage and minimizes back charge requests

- ensures risk monitoring and communications in all project phases

- throughout the project life cycle identifies, assesses, and implements all opportunities for improving results

- negotiates with stakeholders on change requests and incorporates them into contracts

- assesses risks in terms of effects on the business units, defines measures/actions to be taken, and ensures early escalation

- deploy “all risks” insurance plans and contracts

Claim Management

- involves the project team in the identification of claims

- assesses contracts in terms of claim-relevant significance, ensures examination by a legal expert

- puts the strategy for making/mitigating claims rigorously into practice

- at an early stage, inform the customer, management, and project team of scope deviations

- at an early stage, identifies and mitigates external claims

- conducts (jointly with procurement and sales) negotiations on making/mitigating claims

- devises (with business coordinators) the strategy for making/mitigating claims

- enforces legitimate claims and fends off unjustified claims/back charges

Subcontractors/Partner Management

- involves qualified subcontractors/partners in a timely manner

- selects subcontractors/partners according to defined criteria (strategic, technical, and budget)

- define contracts/frame agreements structure, scope, and budget

- rigorously monitors the performance of the subcontractors/partners, conducts timely escalation (in the event of qualitative shortfalls and problems in cooperation), and where there are any discrepancies, initiates timely suitable actions (expediting, escalation, back-charge, claim)

- identifies further opportunities for business with the partners

- review all subcontractors/partners’ proforma invoices prior to their acceptance

Procurement and Logistics

- involves procurement at an early stage according to valid corporate procurement rules

- ensures that all procurement activities comply with the valid processes and regulations

- negotiates based on defined requirements with subcontractors/partners and enters into back-to-back agreements in alignment with the customer contract

- plans the procurement strategy with the procurement officer

- plan and submit the necessary purchase order requests

- check that buyers are sourcing and expediting the suppliers according to the contractually defined lead-time

- support the shipment/custom operations operated and managed by a professional freight/shipping forwarder

Financial Management (only on SAP R/3 PMIS ERP. The project management, project control, costs control skills are not deployable with unsuitable tools like basic-simple ERPs without project-based cost management modules, or project & service management financial processes based only on the use of Office 365 tools)

Working with the Cost Control Manager and the Project Control Team in controlling the projects, envisioning and promptly suggesting corrective and improving actions in line with corporate procedures and working instructions.

Moreover, always involved in the following activities:

- Support the Cost Control Manager and other functions as a business partner

- Prepare together with the Cost Control Manager & Project Control Team for new projects, the setting of Cost Control System: Order Intake, Project Work Breakdown Structure, Execution Budget

- Prepare and Present Project Control Reports together with Cost Control Manager to Management, following Project Review Cycle and ensuring deadlines are met

- Check the progress of financials of the projects (in terms of actual and committed costs) and, based on the physical progress status of the job and considering the updated time schedule to completion, the risk, and opportunities, the technical performance aspects of the project

- Prepare with the Cost Control Manager & the Project Control Team the best estimation to complete about costs, reserves, billing, cash-in, guarantees, hedges

- Control and have at all times full knowledge of all projects-contract’s financial movements within the project scope, ensuring they are correctly and accurately reported

- Enter and maintain project budgets/forecasts/actuals in the ERP system

- In case of interplant-intercompany projects, coordinate with other Costs & Project Controllers to build the consolidated View

- Update the Project lifespan Forecast, on a quarterly basis, together with the Costs Control Manager, and interact with the controlling & sales area for budget and quarterly forecast preparation

- manages the project within the defined financial targets (budget, target costing, target profit)

- ensures compliance with internal finance and reporting standards (SOX)

- optimizes project profitability and ensures business success

- lives P/L responsibility for the project as defined in the agreed forecast target

- initiates invoicing according to project progress

- ensures regular financial control and reporting

- takes strategic viewpoints into account when managing the finances of the project

- support the financial team to recover foreign withholding tax credit retention

- develops targeted financing models in agreement with controllers/credit management team

- define international payments methods, plan and due dates, mitigating credit and foreign currency exchange risk

Networking

- communicates on a cross-sector/division or cluster/region level with internal contacts on opportunities for doing further business

- cooperates with line experts on business development knowledge management

- seeks and actively utilizes sources of information, knowledge, and experience

- analyzes information, knowledge, and experience, and makes project learning available

- conducts a project closure meeting and lessons learned workshop

- seizes opportunities to learn from others and to exchange experience

- coaches/Mentors new project team members according to requirements

Leadership, Communication, Project Interface Management, and Soft Skills

- ensures efficient communication with all relevant stakeholders and project interfaces

- ensures targeted and full communication within the project team

- agrees targets with project staff and delegates defined responsibilities and authority

- monitors the motivation of the project team

- coaches and controls the team/individual members of the staff

- holds feedback sessions with each directly assigned member of the staff

- seeks active feedback (e.g. from members of staff, managers, and customers)

- provides input in the context of the performance management process

- consults manager of staff members concerning their individual training and development

- develops and trains actively newly engaged staff members in close coordination with the resource manager

- provides Know-how in the context of project management and thus serves actively to secure the quality standards

Business Integrity

- seeks and actively utilizes information on current compliance with relevant policies and regulations within the organization: mainly business conduct/tax/financial regulations/EHS (environment, health, and safety)

- involves the respective compliance officer

- forwards all relevant information to the project team members and partners

- sets up a framework to ensure regular checks of the compliance in the project, e.g. by conducting compliance risk assessments at the appropriate milestones/quality checks

Modernization Project Delivery & Commissioning Management:

- review Supply Agreements and extract service obligations by the OEM (own client), the Customer/end-user, and any relevant party into a project achievable list.

- negotiate and manage project commissioning & delivery obligations by working with customers, OEM (own client) team members (Field service manager, Account/Sales Manager, Application Engineer, Logistics), and relevant external stakeholders to ensure successful and timely execution of these obligations.

- develop the project Gantt chart, define the project budget, and keep track of all expenses and manpower, and field instrumentations for each project. Ensure projects are completed within scheduled timeframes and budget.

- manage customer relationships and expectations. Resolve issues and negotiate resolutions to issues causing delays in the delivery of products commissioning-functionalities.

- work collaboratively with internal and external resources in various (engineering, logistics. HSE, etc.) disciplines to determine project priorities and work plans.

- keep the management team and project managers informed of the project status via weekly, monthly reports and the field operations log (useful in case of escalations/disputes)

- identify project risks and propose solutions and preventative measures to manage the risk.

- meeting objectives with project management skills. Scheduling and planning resources and coordinating plant commissioning resources to provide effective early-stage project development support

- ensure commissioning and modernization projects are efficiently, effectively, and safely implemented in accordance with (OEM) department procedures and policies

- scope management – identify any discrepancies and variations in the scope of work

- manage to walk down of planned work, validate acceptance of completed work to design requirements, and validate, approve contractor reports and invoices. Verify procedures, equipment, and resource allocations to avoid conflicts and resolve issues as needed. Leads project meetings with customers (and internally) during the installation and commissioning phase (risk tracker and contingency allocations).

- determine site-specific requirements: including labor, local safety requirements, utility, and work permit costs.

- work with Product Management, Sales Management, and Application Engineers to generate all the field information required for systems integration in the field. Review drawings and set up execution plans with third parties and field service groups.

- communicate with the HQ Engineering team to coordinate the troubleshooting process until it is resolved

- manage customer communication on a routine basis to ensure customer satisfaction.

- develop and negotiate sub-contractor, consultant, or engineering agreements including safety plans, schedules, and scope-of-work necessary to fulfill project requirements.

- manage all aspects of the project schedule from project kickoff to project close-out punch list items including project post-mortem meeting.

- support the field service coordinators to promptly involves the relevant engineering specialists to guide the field engineers team and participate in the conference call or customers meeting

- compile project review report upon completion and offer proposals and suggestions for the organization to improve and deliver a better customer experience

- oversee and monitor processes, materials, safety, and quality, to detect or assess problems

- coordinate inspections and interconnections with the customer.

- coordinate project commissioning and handoff to customer support and/or O&M team.

- coordinate customer training and acceptance

Field Service Support:

- travel to the site during commissioning activities when required to lead the commissioning projects or manage meetings.

- conduct site visits, coordinate experimental investigations and analyze engineering problems, propose solutions and alternatives, and provide recommendations